Load class according to EN 1433

Load class according to EN 1433

up to F 900

up to F 900

up to F 900

up to E 600

up to F 900

Nominal width | System size

Nominal width | System size

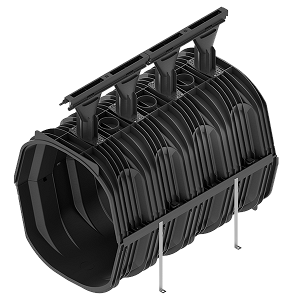

1000, 2000, 3000, 5000, 8000, 10000

NW 200 & 300

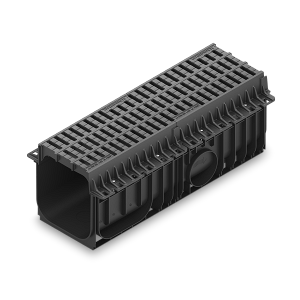

100, 150, 200, 300, 400, 500

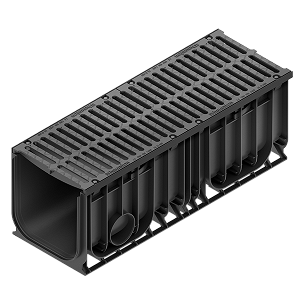

100, 150, 200, 300, 400

300 – 500

Materials of the lower parts

Materials of the lower parts

Modified polypropylene (PP), 100 % recycled composite

Modified polypropylene (PP), 100 % recycled composite

Fibre-reinforced concrete

Modified polypropylene (PP), 100 % recycled composite

Fibre-reinforced concrete or polypropylene (PP)

Angle housing

Galvanised steel or ductile iron edge rail with 40 x 40 mm insertion depth

Moulded as an integral part of the channel body

Depending on the version with FASERFIX or RECYFIX:

Galvanised steel or cast iron frame with 40 x 40 mm insertion depth

Grating variants

Ductile iron grating with lateral concrete anchoring

– Ductile iron gratings

– GUGI ductile iron gratings

Special characteristics

– Radial installations possible

– Large channels for retention

– Channel run without slotted top achievable, for example, under planted areas

– Cable installations can be threaded though throat voids of the channel

– Material combination of recycled PP and ductile iron for adaptability on the construction site and robustness

– Side wings for optimum connection to the concrete surface

– No screws and loose parts on the surface

– Connection between channel and grating encased in concrete for extra safety

– SIDE-LOCK, boltless locking system

– 16 fixing points for grating/metre

– Channel and cover = one component

– Self-centring screw –> automatically finds the correct position

– Polypropylene channel body can be easily machined on site

– Rainwater treatment by surface filtration

– DIBt approval

– Proprietary treatment system: CIRIA SuDS Manual C753 chapter 14

Gradient

– Constant depth

– Stepped fall

– Stepped fall (at NW 200)

– Constant depth

– Constant depth

– Built-in fall (150, 200, 300)

– Stepped fall

– Constant depth

– Stepped fall