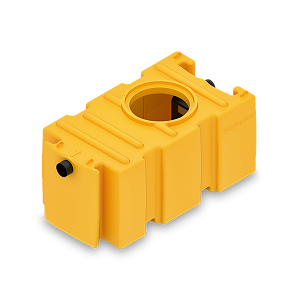

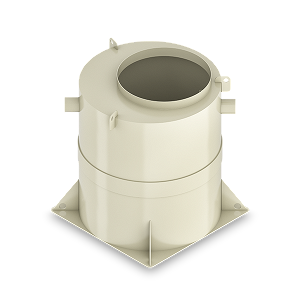

If the waste water entering the separator contains this type of pollution, it is necessary to use a settling tank integrated into the separator or used as a separate device before the separator.

The settling tank slows down the flow of water, and as a result of the sedimentation process in the settling tank, the particles gravitationally denser than water settle to the bottom of the tank and are stored there. In the second phase of wastewater treatment, the phenomenon of flotation takes place, whereby grease particles, due to their density lower than that of water, accumulate on the surface of the water. The inlet and outlet are siphoned which prevents unpleasant odours from escaping from the unit.